|

||

|

29 Aug 2013, 7:55 AM

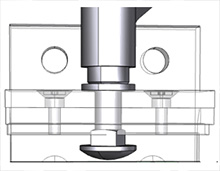

Factories, production lines, manufacturing plants all use a wide assortment of fastener and assembly systems. From the small and meticulous word of the watches assembly industry requiring accuracy and low torque, to heavy duty equipment requiring high performance, all utilize an array of fastener solutions that need to provide crucial operational performance. Fastening threaded joints correctly, the first time, is a challenge. At Andilog Technologies, we understand that torque measurement can be critical, so we want to bring you a large range of torque measurement devices and indicators. Core products that we provide include range from miniature digital torque screwdrivers wrench to handle torque gauge and torque analyzer indicators. This product range has been developed to provide a torque measurement solution to better equip end-user to control and test threaded assemblies and fasteners, as well as to help engineers to design and qualify news fastening solutions. If you want more information on Andilog’s torque gauge and torque tester solutions, have a look here.… |

One of the original and most commonly used method of attaching parts together is by means of a threaded fastener, however the threaded joint and its fastening is a complicated matter.

One of the original and most commonly used method of attaching parts together is by means of a threaded fastener, however the threaded joint and its fastening is a complicated matter.